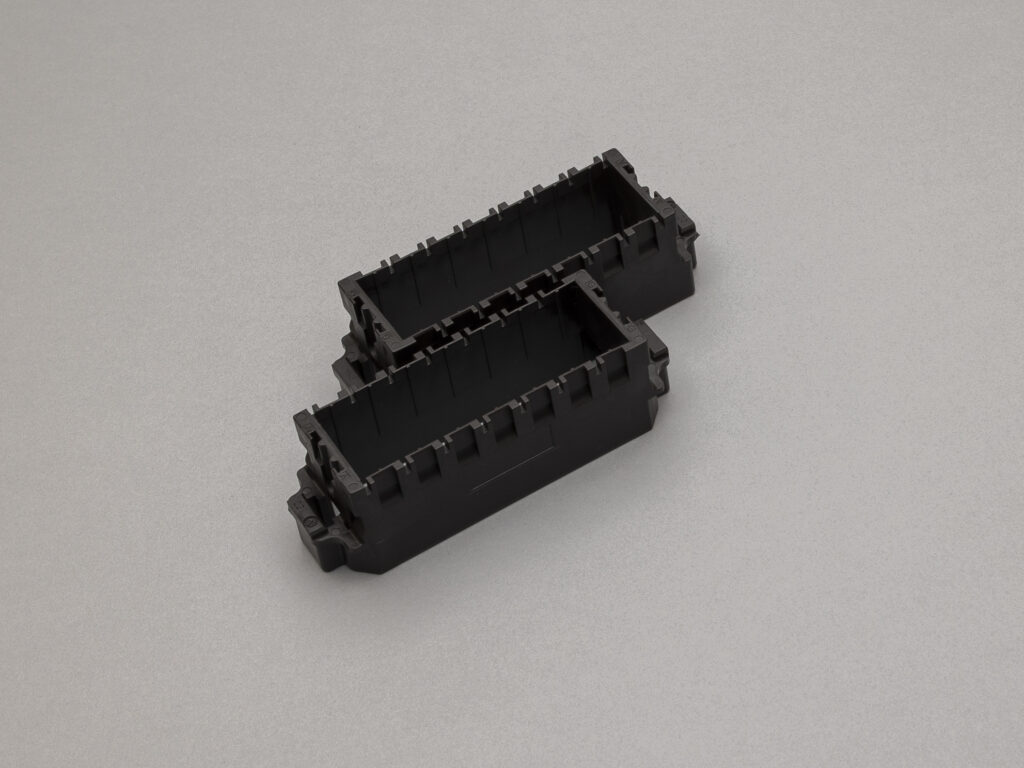

Injection Molding of Plastic Parts

Nativel’s strengths lie in extensive know-how in injection molding production and close cooperation with toolmakers. This ensures high quality standards and cost-effective solutions. Thanks to the long-standing expertise of our employees, flexible adaptations are possible with minimal lead times. In addition to the production of injection moulded plastic parts, Nativel offers assembly of manufactured components. This permits compliance to assembly-specific tolerances.

Injection Molding Machines of 25–200 t

Nativel’s machine park is comprised of 11 injection molding machines by Arburg, Engel and Demag. These include vertical and horizontal machines able to produce plastic parts weighing up to 350 g. With clamping forces of 25–200 t and a maximum tie-bar width of 570 mm, our machines allow for a high degree of production flexibility.

Small to Large Lot Sizes

Nativel offers its customers individual solutions characterised by highest quality standards and precision in workmanship and manufacturing. Lot sizes ranging from 10 thousand to 10 million per year are possible through manual and automatic production in two or three shift operation.

Wide Range of Tools and Materials

Close cooperation with toolmakers enables Nativel to offer a wide range of different and individualised injection moulded parts. Most common materials for the application in the automotive, medical technology and electronics sectors are in use. Nativel manufactures parts from PP, PE, PS, ABS, POM, PA, PBT, PC and TPE, among others. We offer fully automatic production as well as semi-automatic production with inserts.